Digital Flexo Plates

Home / Digital Flexo Plates

Digital Flexo Plates: Revolutionizing Flexographic Printing

Digital flexo plates represent a significant advancement in the field of flexographic printing, offering enhanced precision, efficiency, and quality. Unlike traditional analog flexo plates, which require time-consuming manual processes, digital flexo plates are created using advanced computer-to-plate (CTP) technology. This digital workflow allows for direct transfer of digital images onto the plate, ensuring higher accuracy and consistency. The result is superior print quality with finer details, smoother gradients, and more vibrant colors. Digital flexo plates also offer improved durability and longer press life, making them a cost-effective choice for high-volume printing. The ability to make rapid adjustments and reproduce plates quickly further enhances the flexibility and efficiency of the printing process. This technology is particularly beneficial for industries requiring high-quality packaging, labels, and other printed materials.

Printing Service

Support and competitive pricing to meet all your printing

Digital Scanning

Converting physical documents, imagesinto digital formats

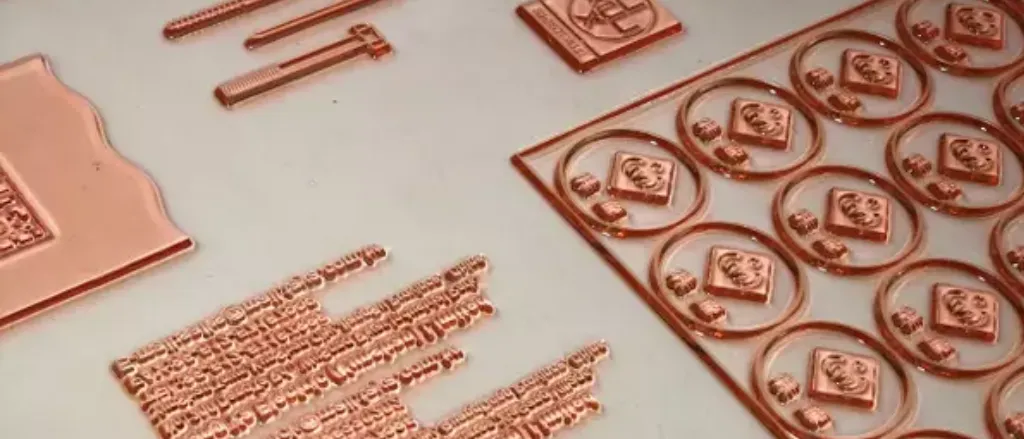

Digital Flexo Plates

Digital Flexo Plates are advanced printing plates used in flexographic printing, created using digital imaging technology.Unlike traditional methods that involve manual plate-making, digital flexo plates are produced directly from digital files, offering greater precision and speed.

Key Benefits of Digital Flexo Plates

Environmental Resistance : The coating serves as a protective barrier, shielding the print from environmental factors such as moisture, UV light, and physical abrasion. This protection helps in preserving the vibrant colors and sharp details of the print over time.

Scratch Resistance: Coated surfaces are less prone to scratches and scuffs, maintaining the integrity and appearance of the print even with frequent handling.

Faster Turnaround : The digital workflow significantly reduces the time required for plate production, allowing for quicker setup and shorter lead times

Rapid Adjustments : Easy and quick adjustments to designs can be made without the need for manual intervention, enhancing overall efficiency.

Longer Press Life : Digital Flexo plates are more durable and can withstand longer print runs, reducing the need for frequent replacements.

Cost-Effective : The extended lifespan of the plates and reduced waste contribute to cost savings in the long run.

Versatility : Suitable for a wide range of substrates, digital flexo plates can be used for various applications, from flexible packaging to corrugated materials.

Adaptability : The technology allows for easy customization and adaptation to different printing needs and specifications.

Reduced Waste : Digital flexo plates reduce waste by eliminating the need for chemical processing and minimizing material usage.

Eco-Friendly Options : Many digital flexo plate systems use environmentally friendly materials and processes, contributing to sustainable printing practices.

Digital Integration : Seamless integration with digital prepress workflows enhances overall production efficiency and allows for better management of print jobs.

Quality Control : Many digital flexo plate systems use environmentally friendly materials and processes, contributing to sustainable printing practices.